EVA vacuum de-aeration units of PUC for the production of grease

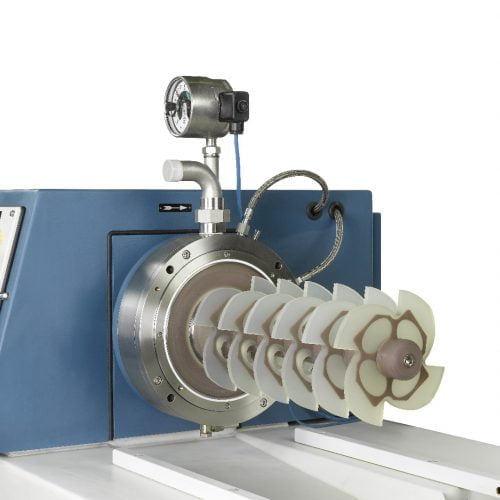

Probst Und Class, the manufacturer of Colloid Mills, also makes complete production units for the production of greases from NLGI 0 to NLGI 6. In these units, the EVA vacuum de-aeration system is providing the continuous de-aeration of these highly viscous products.

Mode of operation:

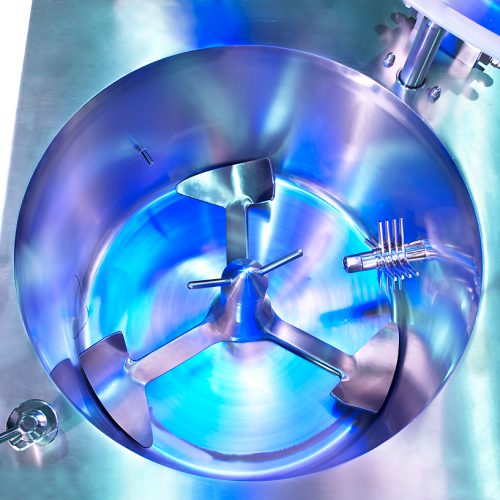

The product to be de-aerated is fed to the vacuum vessel via a distribution system adapted to the characteristics of the product. The product then flows down the inner walls of the vessel as a thin film or in droplet form and collects in the conical bottom section of the vessel for removal. This process is based on the increase in the surface area of the product, which shortens diffusion paths. As a result, gases such as oxygen, which may be finely distributed within the product or adhere to solid particles, are released and can be effectively removed. The temperature of the product remains unchanged during this process.

These EVA vacuum de-aeration units and the PUC colloïde mills can also be used in the production of food products like mayonnaise, ketchup, mustard, sauces, jams, pastes. chemicals,

Also in the pharmaceutical, chemical/petrochemical, cosmetics and food industries EVA vacuum de-aeration units of PUC are used. The size of the vacuum vessel depends on the capacity required and the de-aeration behaviour (viscosity and surface tension) of the product.

PUC EVA vacuum de-aeration units are available for fully automated continuous operation.

Tags : process solutions